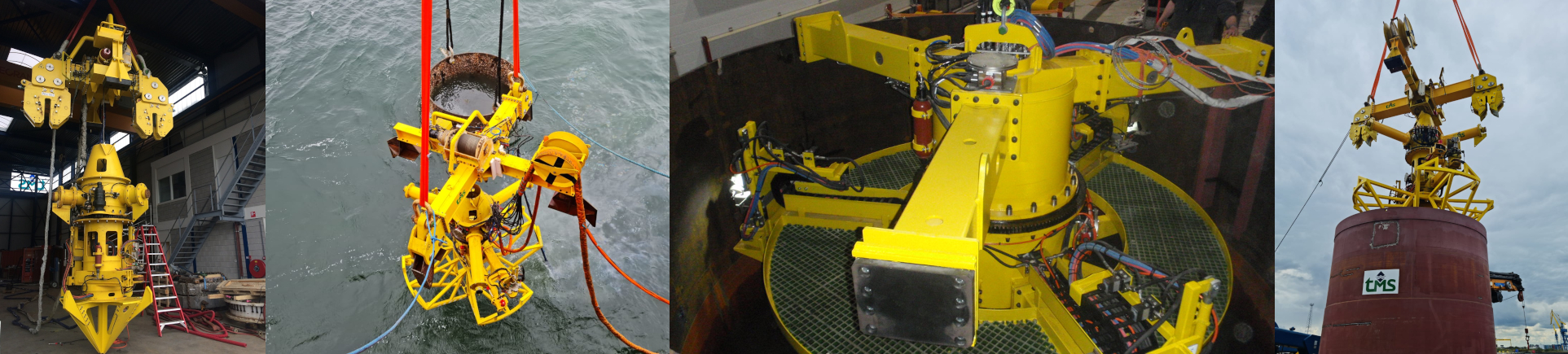

TMS Cutting ROV's

Cutting ROV - Internal Pile Cutting tool

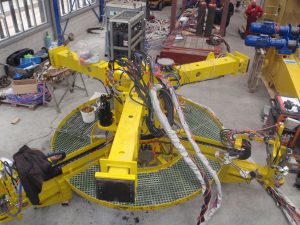

TMS has designed and built an automatic under water Internal Pipe Cutter (IPC) for cutting piles with diameters less than 6 meter. Pipes can be cutted under water automatically by this tool. The tool operates from the inside of the pipe, which enables the ROV to cut the mono pile of wind turbines foundations both under and above seabed level.

Specifications Internal Pipe Cutter:

- applicable for wall thickness over 100mm

- 2 or multiple cutting heads and a follow-up system which intercepts deviations and roundness of the pile wall

- every cutter head is provided with under water lamps and cameras

- depths, speeds and cutting angles can be supervised and set in the control cabin on deck

- starting the cutter heads is done remote controlled

- complete tool including control cabin, gas-/ oxygen bottles, lifting frame and umbilical on one 40 ft flatrack

TMS has developed and supplied a 180t SWL lifting frame with hydraulic clamps for smaller pipe diameters. This lifting frame can be used to lift the cut-off pipe parts. The pile cutting tool is hoisted in this lifting frame and the cut-off pipe parts including cutting tool are lifted as one. The cutting process can be done both autogenous and abressive.

Cutting ROV - Pile Stopper Cutting tool

For the removal of knees which are welded to steel pipes, TMS designed and built the Pile Stopper Cutting tool. These knees are cutted under water automatically. The tool takes position by means of the crane and integrated thrusters.

Specifications Pile Stopper Cutting tool:

- 2 cutter heads with follow-up system

- every cutter head is provided with under water lamps and cameras

- depths, speeds and cutting angles can be supervised and set in the control cabin on deck

- starting the cutter heads is done remote controlled

- complete tool including control cabin, gas-/ oxygen bottles, lifting frame and umbilical on one 40 ft flatrack